Table of Contents

- Introduction: Why Did the Project Manager Cross the Road?

- What Is Lean Project Management Certification?

- Why Should You Get Lean Project Management Certified in 2025?

- How to Get Lean Project Management Certification in 2025?

- Common Myths About Lean Project Management Certification

- Best Tools & Software for Lean Project Management

- 10 Less Commonly Known Facts About Lean Project Management

- Final Thoughts

- FAQs

Introduction: Why Did the Project Manager Cross the Road?

To eliminate waste, of course! (And to get to the APMIC certification page faster!)

In today’s hyper-competitive world, project managers need more than just experience—they need the cutting-edge tools that separate top performers from the rest. That’s where Lean Project Management Certification comes in. It’s not just another buzzword; it’s a game-changing approach designed to help professionals eliminate inefficiencies, streamline workflows, and deliver maximum value. So, if you’re ready to future-proof your career and take charge like a project management ninja, let’s dive into the world of Lean project management certification and explore how you can use it to dominate your field in 2025!

What Is Lean Project Management Certification?

Lean Project Management Certification is an industry-recognized qualification that validates your ability to optimize processes, reduce waste, and maximize efficiency in project execution. It is rooted in the Lean methodology pioneered by Toyota in the 1950s, which revolutionized manufacturing and later influenced sectors such as IT, healthcare, and finance.

Understanding the history of Lean project management can give you deeper insights into its evolution—explore its origins and impact here.

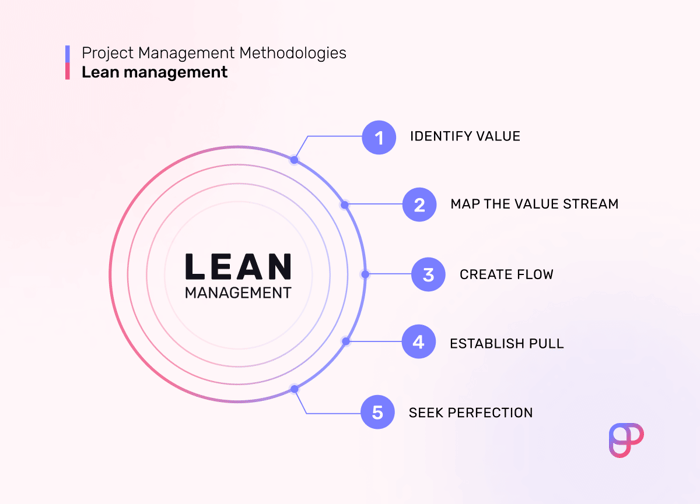

How Does Lean Project Management Work?

The core philosophy of Lean project management revolves around continuous improvement (Kaizen), waste reduction, and value maximization. This means:

Identifying and eliminating non-value-adding activities

Enhancing team collaboration and stakeholder engagement

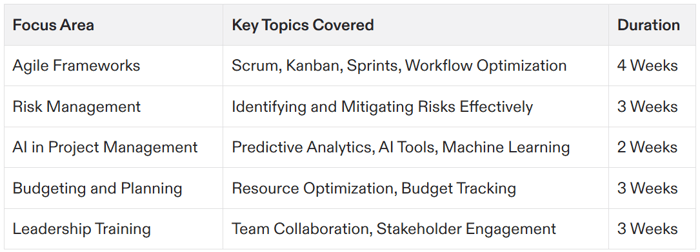

Using data-driven decision-making tools like Kanban, Value Stream Mapping, and Root Cause Analysis

With a Lean certification, you don’t just manage projects—you engineer success! If you're looking for the best project management certification program to complement your Lean expertise, explore the top-rated options.

Why Should You Get Lean Project Management Certified in 2025?

Here’s why getting Lean-certified is no longer optional—it’s a must-have:

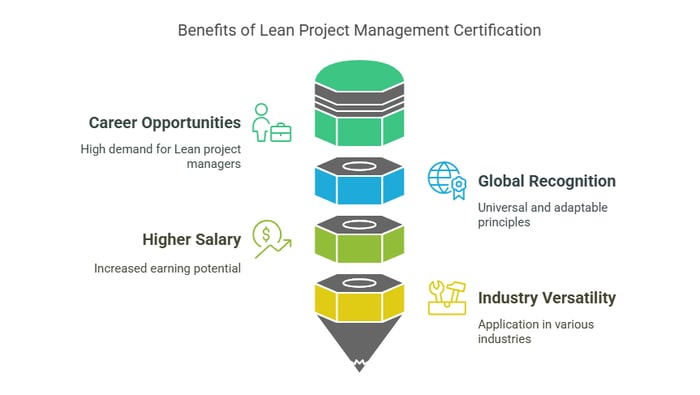

1. Exploding Career Opportunities

Lean project managers are in high demand across multiple industries, from tech startups to Fortune 500 companies. According to LinkedIn’s 2025 job trends report, Lean-certified professionals earn up to 35% more than their non-certified peers.

2. Global Recognition

Unlike niche project management frameworks, Lean principles are universal and adaptable across all industries. Certifications like Lean Six Sigma and APMIC credentials are globally recognized, making you a valuable asset anywhere in the world.

3. Higher Salary & Faster Promotions

A Lean Project Management Certification increases earning potential. Studies show that professionals with Lean certification earn an average of $10,000–$25,000 more annually than those without. (Source: Project Management Institute).

4. Industry Versatility

Lean principles aren’t just for manufacturing. They’re widely used in:

Healthcare: Reducing patient wait times

Finance: Eliminating inefficiencies in banking operations

IT & Software: Enhancing Agile development processes

Construction: Streamlining resource allocation

Pro Tip: For those just starting their journey, choosing the best entry-level project management certification can set a strong foundation—discover the most recommended programs.

How to Get Lean Project Management Certification in 2025?

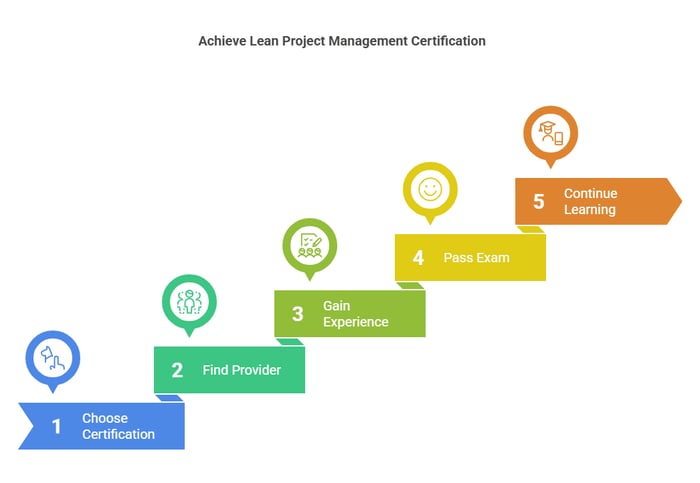

Step 1: Choose the Right Certification

There are multiple Lean certifications, including:

Lean Six Sigma (Yellow, Green, Black Belt)

Certified Lean Project Manager (CLPM)

Lean Agile Project Management Certification

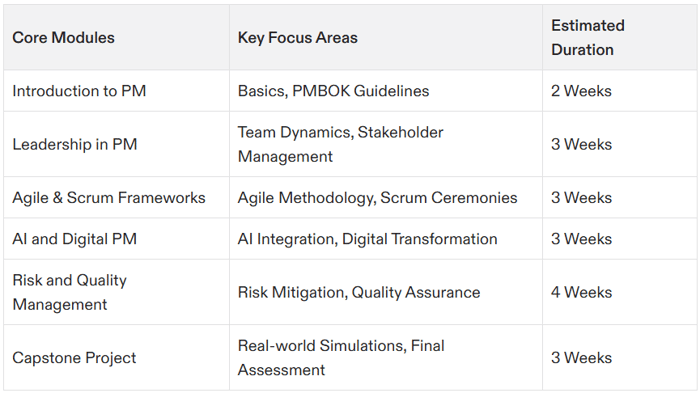

Step 2: Find a Reliable Training Provider

Not all training providers are created equal. Look for certifications that offer real-world application, hands-on training, and industry-recognized credentials. APMIC is a leading platform that offers 400+ modules tailored for professionals.

Step 3: Gain Hands-On Experience

Theory is great, but practical experience is king. Many certification programs now offer real-world project simulations, case studies, and interactive exercises to ensure you’re ready to apply Lean methodologies in your job from day one.

Step 4: Pass the Certification Exam

Certification exams test your understanding of Lean principles, tools, and implementation techniques. Be sure to use mock exams and practice tests to boost your confidence before the big day.

Step 5: Keep Learning & Stay Certified

Lean is an ever-evolving methodology. Top professionals stay ahead by continuously updating their knowledge, attending industry workshops, and networking with other Lean experts.

Common Myths About Lean Project Management Certification

Despite its widespread adoption, several myths surround Lean Project Management Certification that might mislead professionals. Let’s debunk them:

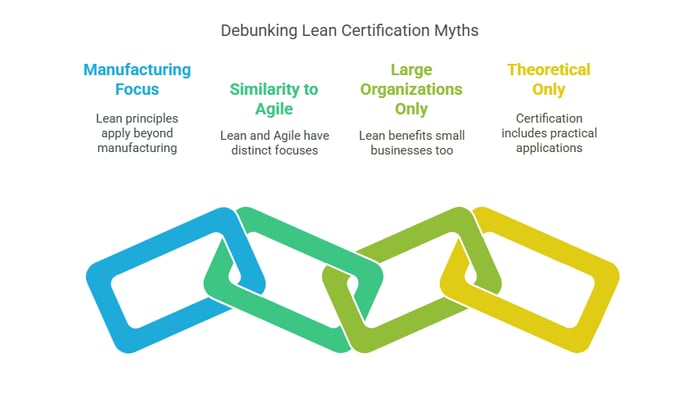

Myth #1: Lean is only for manufacturing

While Lean principles originated in Toyota’s manufacturing system, they have since evolved to optimize processes in healthcare, IT, finance, retail, and even startups. For example, hospitals use Lean to reduce patient wait times, and tech companies apply it to streamline software development cycles.

Myth #2: Lean is the same as Agile

Both methodologies emphasize adaptability, but Lean focuses on waste elimination and efficiency, while Agile is about continuous delivery and flexibility. In fact, many organizations combine both for Lean-Agile project management.

Myth #3: Lean certification is only useful for large organizations

Small businesses and startups can benefit just as much, as Lean helps in cutting costs, improving efficiency, and enhancing customer satisfaction without requiring large-scale resources.

Myth #4: Lean certification is only about theory

High-quality Lean Project Management Certifications, such as those offered by APMIC, include practical applications, case studies, and real-world problem-solving to ensure professionals gain hands-on experience.

Real-World Case Studies of Lean in Action

Lean project management has transformed businesses worldwide. Here are three real-world case studies:

1. Healthcare: Virginia Mason Medical Center (USA)

By applying Lean principles, Virginia Mason reduced patient wait times by 43% and improved overall hospital efficiency by increasing staff productivity without burnout.

2. Manufacturing: Boeing’s Aircraft Production

Boeing integrated Lean methodologies to eliminate production bottlenecks, reducing assembly time for airplanes by over 25% while maintaining superior quality.

3. Tech: Intel’s Lean Transformation

Intel adopted Lean project management to optimize semiconductor production, resulting in 30% higher production efficiency and a significant reduction in manufacturing costs.

These cases prove that Lean principles are universally applicable, making certification a valuable asset.

Best Tools & Software for Lean Project Management

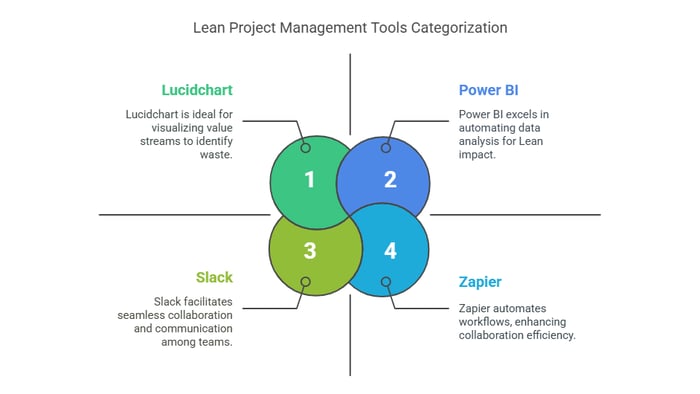

Using the right tools can supercharge your Lean project management efficiency. Here are some top software options:

- Kanban Boards (for workflow visualization): Trello, Jira, Monday.com

- Value Stream Mapping Tools (to identify waste): Lucidchart, Miro

- Process Automation Software (for efficiency): Zapier, Asana, Smartsheet

- Data Analytics & Reporting (for measuring Lean impact): Power BI, Tableau

- Collaboration & Communication Tools (for seamless teamwork): Slack, Microsoft Teams

Each of these tools aligns with Lean principles, helping project managers cut inefficiencies and enhance productivity.

Lean Project Management vs. Traditional Project Management

A structured comparison of how Lean differs from traditional project management:

| Feature | Lean Project Management | Traditional Project Management |

|---|---|---|

| Focus | Reducing waste & maximizing value | Following strict project scope & deadlines |

| Flexibility | High – adapts to changing requirements | Low – follows predefined plans |

| Process Flow | Continuous improvement (Kaizen) | Sequential, phase-based (Waterfall) |

| Resource Management | Lean, minimal waste, just-in-time delivery | Preallocated resources, risk of overuse |

| Customer Value | Prioritizes customer value and feedback | Delivers based on pre-determined requirements |

| Industries Used | Tech, manufacturing, healthcare, startups | Construction, government, large enterprises |

If your goal is to increase efficiency, reduce waste, and deliver better value, then Lean Project Management Certification is the way forward. If you want to compare different Lean certification options, you can check out the industry guide.

Career Paths After Getting Lean Certified

Once you earn a Lean Project Management Certification, new career opportunities open up. Some of the high-demand roles include:

- Lean Project Manager – Oversees process improvements and ensures waste elimination.

- Continuous Improvement Manager – Drives efficiency projects within organizations.

- Process Analyst – Evaluates and optimizes workflows for better output.

- Operations Manager – Implements Lean principles across business operations.

- Quality Assurance Manager – Ensures processes meet high standards with minimal waste.

Companies worldwide actively seek Lean-certified professionals, offering higher salaries and leadership opportunities.

How to Use Lean Beyond Project Management

Lean is not just a project management framework—it’s a mindset that applies to everyday business operations and personal productivity.

🔹 Lean in Business Operations:

- In customer service, companies use Lean to reduce response times and improve resolution rates.

- In finance, Lean helps streamline budgeting and cost reduction strategies.

🔹 Lean for Personal Productivity:

- Using the Pomodoro technique to avoid wasted time.

- Applying Kanban boards to track personal projects efficiently.

🔹 Lean in Team Collaboration:

- Encouraging short daily meetings instead of lengthy, unproductive sessions.

- Using real-time feedback loops to improve team efficiency.

By adopting Lean principles in everyday life and business, you achieve greater efficiency in all aspects.

The Future of Lean Project Management in 2025 and Beyond

As industries digitize and evolve, Lean project management is also adapting.

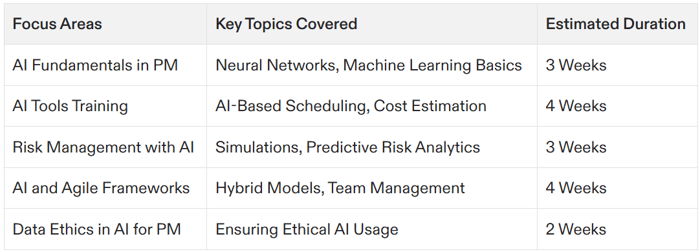

🌟 AI & Automation in Lean: AI-powered analytics help predict bottlenecks in project workflows before they occur.

🌟 Remote-Friendly Lean Strategies: The rise of hybrid workforces requires Lean methodologies to focus on asynchronous collaboration and cloud-based efficiency tools.

🌟 Sustainability & Lean: Many companies are combining Lean principles with green initiatives, minimizing waste while adopting eco-friendly practices.

By staying updated with Lean trends, professionals can future-proof their careers and continue delivering high-impact results.

10 Less Commonly Known Facts About Lean Project Management

The term 'Lean' was coined in the 1980s – Harvard Business Review

Toyota’s Lean model saved them from bankruptcy

Lean methods reduce project costs by up to 40% – Forbes

Lean Six Sigma originated from Motorola, not Toyota – Motorola University

Lean tools are used in the space industry – NASA

Hospitals use Lean to reduce patient wait times by 30% – Health Affairs

Lean and Agile hybrid models boost productivity by 25% – McKinsey & Company

Tech giants like Amazon use Lean principles in logistics – Amazon Blog

Lean improves employee satisfaction and retention – Gallup

Lean helps reduce project failure rates by 50% – PMI

Final Thoughts

Mastering Lean Project Management isn’t just about passing an exam—it’s about becoming a leader in efficiency, innovation, and value delivery. If you’re serious about advancing your career, check out APMIC for the best Project Management Certifications and take the next step toward professional excellence!

FAQs

Is Lean Project Management only for manufacturing?

No! While it started in manufacturing, Lean is now widely used in healthcare, IT, finance, construction, and even government sectors.

How long does it take to get Lean Project Management Certified?

Depending on the level, it can take a few weeks (Yellow Belt) to several months (Black Belt).

What’s the difference between Lean and Six Sigma?

Lean focuses on waste elimination, while Six Sigma emphasizes defect reduction using data-driven methods.

Is Lean Certification difficult?

It depends on your experience. Beginners can start with Lean Yellow Belt, which is relatively easy to grasp.

Can I get Lean Project Management Certification online?

Yes! Many platforms, including APMIC, offer self-paced online courses.

Do Lean certifications expire?

Some, like Lean Six Sigma, require renewal every few years, while others are lifetime certifications.

Can Lean Project Management be combined with Agile?

Absolutely! Lean principles complement Agile by removing bottlenecks and streamlining processes.

Does Lean Project Management Certification help with job promotions?

Yes! Certified professionals are often fast-tracked for leadership roles due to their efficiency-driven mindset.